Fast and customizable:

configure your system individually

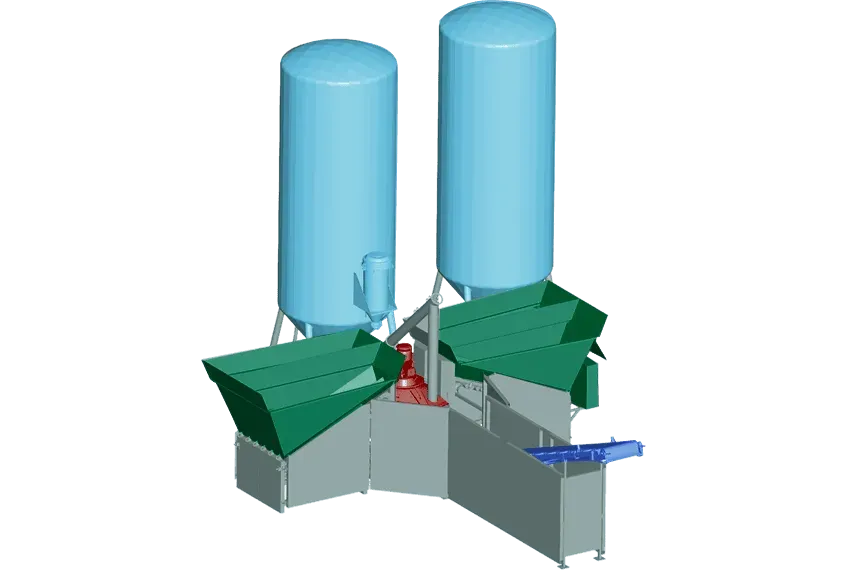

The modular design of our concrete filling stations allows you to build a setup tailored to your requirements and local conditions. The core of the system is the mixing module. Available are planetary mixers with a batch capacity of 0.5 m³ or 1 m³. You can choose the size of your cement silo yourself: standard 30 m³, optionally increased to 33 m³. The standard silo is equipped with a cement dust filter and a level sensor. BETON2GO

Features and Benefits

Fully automated mixing plant for producing proven concrete mixes

Compact design — required installation space starting from 70 m²

Expand your product range with fresh concrete

Fast ROI: your investment pays off within 3–4 years

Cement Silo with Cement Dust Filter

Gravel Storage Chamber with Control System

Planetary Mixer

Discharge Conveyor Belt

Cement Silo with Cement Dust Filter

Choose a standard silo with 30 m³ or increase the volume up to 44 m³. The standard silo is equipped with a cement dust filter and fill-level monitoring.

Gravel Storage Chamber with Control System

Choose two, four, or six chambers, each with 3.5 m³, expandable to 5 m³. Loading is possible with shovel widths up to 3,200 mm, extendable to 3,500 mm.

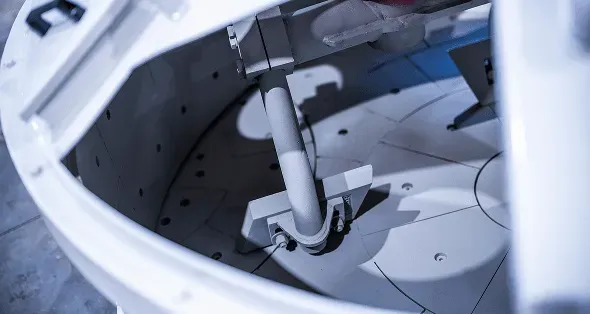

Planetary Mixer

The core of the system is the mixing module. A planetary mixer is available with an hourly output of up to 30 m³ per hour.

Discharge Conveyor Belt

- Standard length: 8 m with a discharge height of 3.05 m

- Extendable to 9 m (discharge height 3.30 m)

- Extendable to 11 m (discharge height 4.03 m)

Planetary Mixer

Choose between a 0.5 m³ or 1.0 m³ planetary mixer with an hourly output of up to 15 m³ or 30 m³ respectively.

Sand and Gravel Storage

Choose two, four, or six chambers, each with 3.5 m³, expandable to 5 m³.

Discharge Conveyor Belt

The standard length of the discharge conveyor belt is 8 m with a discharge height of 3.05 m. It can be extended to 9 m (discharge height 3.35 m) or 11 m (discharge height 4.03 m).

Cement Silo

The standard silo capacity is 30 m³. Optional silos with larger volumes are available.

Mixing Capacity

Up to 15 m³ / 30 m³ per hour with a 0.5 m³ / 1 m³ mixer

Installation Time

Assembly of the components in approx. 4 hours

Cleaning Process

20–30 minutes per day — dry cleaning

| Variant | MA 15-2P | MA 15-4P | MA 30-4P | MA 30-6P |

|---|---|---|---|---|

| Batch size | 0,5 m³ | 0,5 m³ | 1 m³ | 1 m³ |

| Mixer volume | 0,75 m³ | 0,75 m³ | 1,5 m³ | 1,5 m³ |

| Required power input | 28 kW | 28 kW | 48 kW | 48 kW |

| Hourly output | up to 15 m³ | up to 15 m³ | up to 30 m³ | up to 30 m³ |

| Electrical fuse rating | 32 A | 32 A | 63 A | 63 A |

| Planetary mixer diameter | 1900 mm | 1900 mm | 2600 mm | 2600 mm |

| Aggregate hopper size | 2 x 3,5 m³ | 4 x 3,5 m³ | 4 x 3,5 m³ | 6 x 3,5 m³ |

| Required installation area | approx. 80 m² | approx. 100 m² | approx. 100 m² | approx. 120 m² |

| Hopper filling height | 2,47 m | 2,47 m | 2,57 m | 2,57 m |

| Wear-part quality | Chrome cast iron / chromium carbide (HRC 54–58) | Chrome cast iron / chromium carbide (HRC 54–58)) | Chrome cast iron / chromium carbide (HRC 54–58) | Chrome cast iron / chromium carbide (HRC 54–58) |

| Cement silo | 30 m³ (optional up to zu 44 m³) | 30 m³ (optional up to 44 m³) | 30 m³ (optional up to 44 m³) | 30 m³ (optional up to 44 m³) |

| Number of mixing arms | 4 | 4 | 6 | 6 |

| Concrete mix recipes | up to 100 | up to 100 | up to 100 | up to 100 |

Staff-free operating concepts for your requirements

Choose the operating solution that best suits your business. Whether personal sales at the counter or a self-service terminal for your customers — we offer versatile systems tailored to your needs. Each option is designed to simplify the ordering process, increase efficiency, and meet the expectations of both operators and end customers.

Building-Material Kiosk

A fully automated self-service terminal — fast, independent, and usable even outside business hours.

Learn more